Name: Lucy

Tel: +86-13312154946

E-mail: info@ystinjectors.com

Add: Jinyuan Building, 57 Hubin South Road, Xiamen, Fujian

Skype: yistong-cr@hotmail.com

whatsapp: 8613312154946

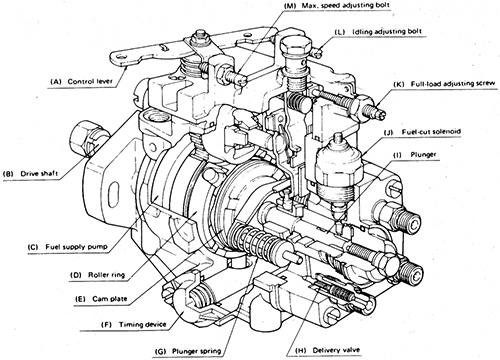

The plunger of the VE distributor pump has both pressure and distribution functions during operation. The rotation speed is 1000-2000r/min, and the pump diesel is 4~6 times per revolution, and the matching tolerance is only 0.003mm, Slightly careless, extremely easy to get stuck. Stuck position in plunger is usually in two locations. First, the plunger and the sleeve are stuck. At this moment, the plunger is likely to be broken. After the engine is turned off, it can no longer be started. No diesel is ejected from the head of oil pump, and the throttle valve does not respond. Second, It is stuck between the plunger and the bleed ring . When the bleed ring is working, it only slides on the surface of the plunger and does not rotate. Once it is stuck, the ring rotates synchronously with the plunger, The head of ball on the speed lever assembly does not allow the ring to rotate. Therefore, under the action of a strong gyroscopic moment, the head of ball is crushed and the lever assembly is forcibly twisted. At the moment of the jam, the positioning pin on the cam disc is likely to be cut.

1. Unclean fuel is the main cause of jamming.

(1) Water or corrosive liquid in diesel, accidentally added to gasoline, low-quality diesel etc., causing corrosion and damage the fluid-film, causing jamming.

(2) The filter fails and tiny hard particles enter the pump causing the card to die.

(3) The diesel pump is not maintained for a long time. Because the pump is installed on the side of the engine, it is often in a high temperature statement. The hydrocarbon compounds in the fuel are cracked into tiny carbon particles, which adheres to the wall of each part. Over time, they gradually accumulate into tiny particles. Once the particles enter the high-speed operation. In the precision sports pair, it is also one of the causes of the card death.

(4) The pump cushion is a rubber that has been subjected to torque for a long time and is constantly subjected to impact load. It is easy to age and easily peels off into small particles after aging. Once these small particles enter the plunger chamber, the plunger may be stuck.

2. Improper operation during commissioning is also one of the reasons for the stuck. The plunger rotates at high speed in the plunger sleeve. The lubrication and heat dissipation between the surfaces of the plunger are all carried out by a small amount of fuel released during the diesel pump distribution process. The plunger cannot be dissipated and lubricated, and serious malfunctions may occur. For example, when the solenoid valve is not connected to the power supply during commissioning, or the electric solenoid valve does not work after the power is turned on; when the diesel stop, speed is adjusted, the test bench runs for a long time, and a large of fuel is discharged from the bleed ring without the diesel is forced out of the dispensing orifice. In this case, the plunger and the surface of the sleeve are free of oil lubrication and heat dissipation, and it is likely to be stuck.

3. Hot diesel pump pouring cold water may also cause the diesel pump to be stuck in normal operation. The diesel pump is generally hot. At this time, it is not appropriate to cause the diesel pump to encounter cold water, avoiding shrinkage of the distributor head casing and causing the plunger to be stuck.

Common Rail Nozzles

Common Rail Nozzles