Name: Lucy

Tel: +86-13312154946

E-mail: info@ystinjectors.com

Add: Jinyuan Building, 57 Hubin South Road, Xiamen, Fujian

Skype: yistong-cr@hotmail.com

whatsapp: 8613312154946

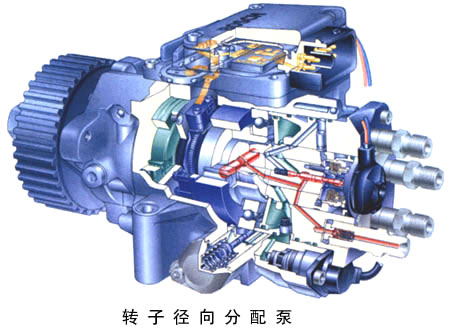

DPA type distribution pump is mainly composed of drive mechanism, secondary vane type feed pump, high pressure distribution pump head and oil quantity control valve. In addition, the mechanical governor is installed in the distribution pump, and the injection advancer is mounted on the external drive mechanism of the distribution pump, including the spline drive shaft and the spline sleeve, and is driven by the crankshaft timing gear.

Working Procession:

1. Oil entering process

The clean diesel oil filtered by the diesel filter is pumped into the axial oil hole of the distribution sleeve by the secondary vane type feed pump, thereby entering the annular oil groove of the distribution rotor, and then reaching the distribution sleeve through the hole of the oil control valve. When any one oil inlet holes in the distribution rotor is rotated to align with the oil distribution hole of the distribution sleeve, the diesel oil enters the center oil hole and the plunger hole,then finish the oil inlet process.

2. Pressure diesel process

When the distribution rotor is rotated a certain angle, the roller rolls up the inner cam disk and reaches the top of the cam disk. During this time, opposing two plungers move inward, and the diesel in the plunger bore is pressurized. At the same time, the distribution hole is in connection with one of oil outlets in the distribution sleeve, whereby the high pressure diesel is supplied to the injector.

3. Diesel stop process

When the distribution rotor rolls down from the top end of the inner cam disk, the plunger barrel moves outward under the action of centrifugal force and oil pressure, the volume of the plunger hole increases, the oil pressure drops rapidly, and the injector stops injecting oil.

4. Adjustment of maximum fuel supply

The maximum fuel supply per cycle of the DPA type distribution pump is adjusted by changing the plunger stroke. The larger the plunger stroke is , the greater of the maximum fuel supply is. However, the end point of the oil supply depends on the highest point of the inner cam disk and cannot be changed. Therefore, changing the plunger stroke can only change the starting point of fuel supply. Since the lugs at both ends of the roller seat are embedded in the eccentric arc grooves of the front and rear control plates, the movement of the roller seats and the rollers is limited by the outer edges of the curved grooves. When the front and rear control plates are rotated counterclockwise, an arc of an eccentric arc groove closer to the center is in connection with the roller seat lugs. At this time, after the fuel supply start point is delayed, the plunger stroke is reduced and the oil supply amount is small; Turn the front and rear control panels clockwise. At this time, the roller seat lugs are in contact with an eccentric arc farther from the center. The oil supply starting point is advanced, the plunger stroke is increased, and the oil supply amount is correspondingly increased.

5. Oil mass control valve

The function of the oil mass control valve is to control the oil supply amount by changing the oil mass control valve through the section as the engine load changes due to the adjustment of the maximum fuel supply amount. The oil mass control valve is operated by a governor. The control valve body is machined with a straight groove and connection with the oil inlet of the distribution sleeve. When the governor pulls the pull rod pin, the oil mass control valve rotates left and right, thereby changing the passage area of the diesel oil, that is, changing the oil supply amount.

Available item for distribution rotor for DPA pump:

7123-340R 4/8.5L DPA 2 No

7123-340S 4/8.5R DPA 2 No

7123-340T 4/9L DPA 2 No

7123-340U 4/9R DPA 2 No

7123-340W 4/9.5R DPA 2 No

7123-345U 6/9R DPA 2 No

7123-909T 6/9L DPA 2 No

7139-130T 4/9L DPA 2 No

7139-235G 3/8R DPA 2 No

7139-360U 6/9R DPA 2 No

7139-709W 3/9.5R DPA 2 No

7139-764S 3/8.5R DPA 2 No

7139-764T 3/9L DPA 2 No

7139-92Y 6/10R DPA 2 No

7180-572Y 6/10R DPA 2 No

91Y 6/10R DPA 2 No

908V 6/9.5L DPA 2 No

7180-600L 4/7R DPA 4 No

7180-650S 3/8.5R DPA 2 Yes

7180-647U 4/9R DPA 2 Yes

7180-611W 3/9.5R DPA 2 Yes

7180-613W 3/9.5R DPA 2 Yes

7180-655L 6/7R DPA 4 Yes

7180-668W 4/9.5R DPA 2 Yes

7180-819U 4/9R DPA 2 Yes

7180-965L 4/7R DPA 4 Yes

7180-977S 3/8.5R DPA 2 Yes

344W 4/9.5R DPA 2 Yes

641L 4/7R DPA 2 Yes

645L 4/7R DPA 2 Yes

698U 4/9R DPA 2 Yes

800L CI 4/7R DPA 4 Yes

547L 4/7R DPA 4 Yes

727L 6/7R DPA 4 Yes

927S 3/8.5R DPA 2 Yes

976L 3/7R DPA 4 Yes

Common Rail Nozzles

Common Rail Nozzles